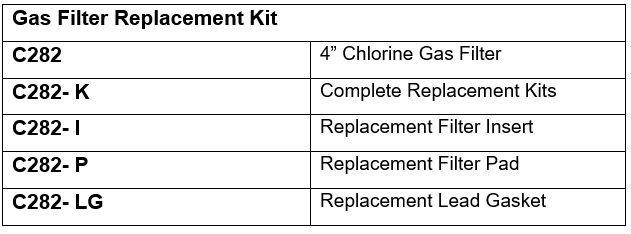

CHLORINE GAS FILTER

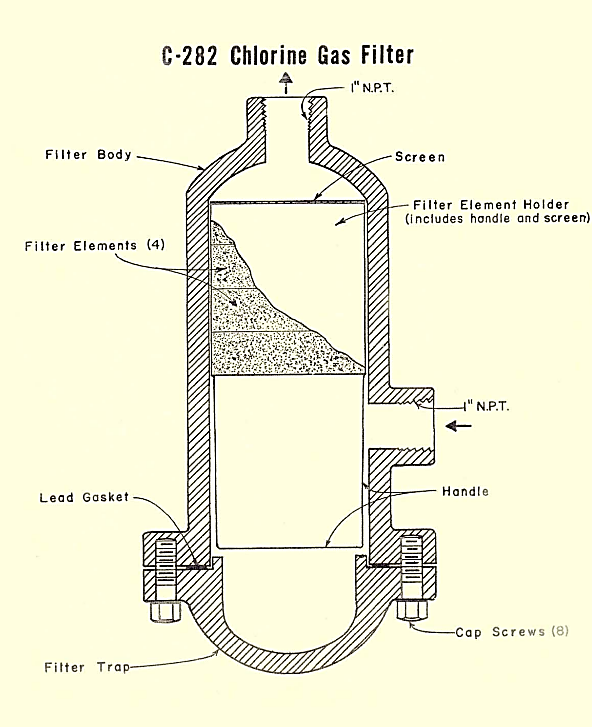

Impurities are inherent in chlorine gas because it is packaged in steel containers. The principal impurity being Ferric Chloride. The amount of Ferric Chloride that deposits out in a chlorine gas system is a function of the quality of the chlorine used. Impurities will always precipitate out of gas if it re-liquefies. This is a common occurrence at points where there is a sudden pressure drop or varying temperatures. A chlorine filter will remove the nuisance causing impurities in chlorine gas. The filter has two chambers. The lower portion acts as a trap for liquid impurities. The sudden enlargement decreases the velocity so that gas is unable to carry entrained droplets of liquid chlorine which is high in Ferric Chloride. The upper portion has a removable filter cartridge. The filter element is especially impregnated so that the Ferric Chloride “plates out” rapidly as it passes through the element. Therefore, the filter acts as both a filter and a condensate trap. The C-282 Filter is made of 25,000 lb. Tensile strength grey iron castings and is rated at 560 PSI working pressure. The C-282 filter should be used on any installation using one ton chlorine cylinders regardless of chlorination capacity and on any installation using an evaporator.

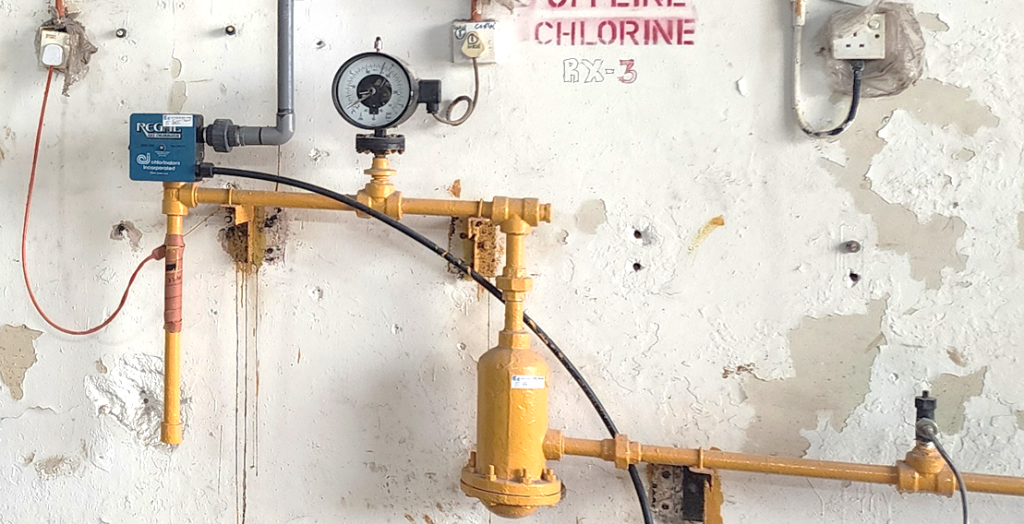

The C-282 Filter is made of high tensile grey iron and is rated at 35bar working pressure. Liquid withdrawal – Note the filter is placed Immediately downstream from the evaporator but ahead of the chlorine pressure. Gas withdrawal – Note the filter is placed as closed as possible to the chlorine containers. In either case always install filter upstream from any reducing valve.

THE C282 FILTER SHOULD BE USED ON ANY INSTALLATION USING ONE TON CHLORINE CYLINDERS REGARDLESS OF CHLORINATOR CAPACITY, AND ON ANY INSTALLATION USING AN EVAPORATOR.

Connection Inlet/Outlet = 1” FNPT

Chlorine Gas filters are specifically designed to filter impurities in order to protect the vacuum regulator and other downstream equipment. All container manifold systems should incorporate such a filter. In order to reduce corrosion and improve filter performance, it is best to design the manifold so that the filter will not frequently have liquid chlorine resting inside it. Such filters typically employ some type of fiberglass filter media. The filters require periodic cleaning and filter media replacement at a rate that is dependent on the chlorine gas feed rate, the quality of the chlorine gas, and the filter design.