CHLORINE LEAD GASKET

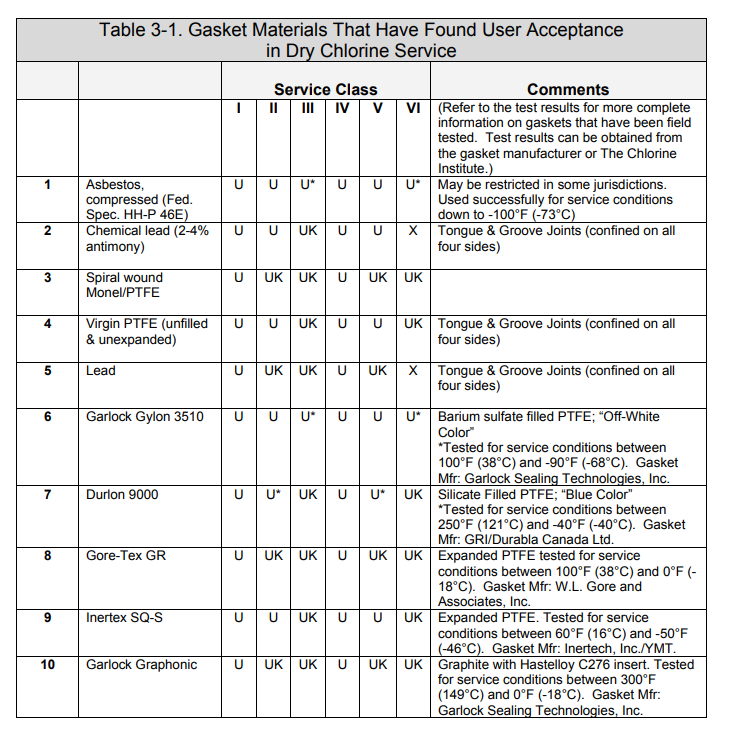

Chlorine is a highly aggressive oxidizer that reacts with many metals and organic compounds. Chemical compatibility and resistance to chlorine are key criteria in the selection of a chlorine gasket material. Service conditions, including contact with dry or wet chlorine, must be taken into account when assessing chemical resistance. Because all gasket materials are porous, a compressive load sufficient to reduce this porosity must be applied. If the initial load is insufficient or if there is a loss of gasket compression, porosity allows the system pressure to push the contained fluid into or around the gasket, leading to gasket degradation, leakage, or blow-out. Material factors such as gasket creep and bolt relaxation, and most importantly, installation practices or flange make-up can affect gasket compression. When choosing a gasket material, compressibility, recovery, creep relaxation, sealability, tensile strength, and stress required to seal should be considered. Proper gasket installation and maintenance is a critical component of a leak-free chlorine system. The installation must create the proper compressive force to provide sufficient friction between the gasket and the flange, and provide sufficient compression to reduce the gasket material porosity to provide the proper seal. It is imperative that personnel be trained to install gaskets correctly.

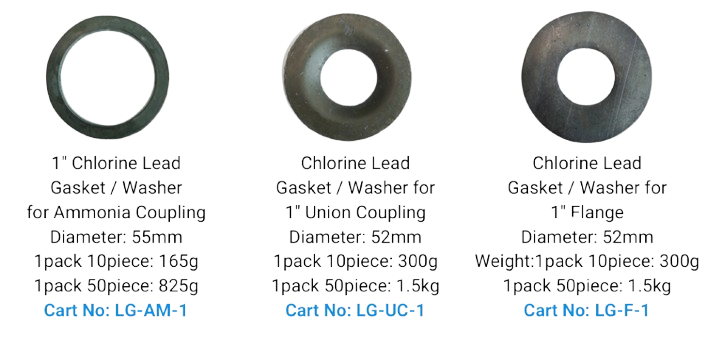

It is imperative to use the correct lead gasket as indicated in the parts drawing for the equipment. Using a lead gasket other than what is indicated in the parts drawing can result in serious injury and damage. After any lead gasket seal has been made it must then be checked for leaks. Systems feeding chlorine gas can use ammonia fumes to detect chlorine gas leaks. The ammonia fumes will mix with any leaking chlorine gas to create a visible white smoke. In other systems it may be necessary to use Nitrogen or dry air to pressure test for leaks. It’s important to check lead gasket seals for leaks often. While a leak may not initially be present, a leak can occur over time. Leaking lead gasket seals should first be tightened to try and stop the leak, but should the leak persist, the system must be evacuated and the lead gasket replaced. Any time a lead gasket seal is broken it should be resealed using a new and undamaged lead gasket of appropriate size and thickness. Never reuse a lead gasket or use multiple stacked lead gaskets as the seal will not be as good as using a new lead gasket or one of appropriate thickness. Reusing lead gaskets and/or multiple lead gaskets stacked together is an unsafe practice that can lead to injury and damage. NOTE: Some lead gasket seals require that they be tightened to a defined torque specification. The Operation & Maintenance Manual for the equipment should be checked for these torque specifications.

A lead products safety data sheet (SDS) should be kept on hand for reference. This document will contain useful information for the handling, storage and disposal of lead gaskets. The disposal of lead gaskets should be considered. To prevent soil and water contamination, lead gaskets should be disposed of in accordance with regional, national and local laws and regulations. Used and damaged lead gaskets should never be discarded with regular trash; instead, these gaskets should be collected and provided to a metal-recycling company. Metal-recycling companies help dispose of and recycle lead waste in a safe and environmentally conscious manner.